HVAC filters are essential components in heating, ventilation, and air conditioning systems, designed to trap dust, pollen, dirt, and other airborne particles from the air that flows through the system. Their primary function is to protect the HVAC equipment from internal damage caused by debris and to improve indoor air quality by reducing the presence of pollutants and allergens.

These filters are typically installed at the intake or return air side of the system, where they act as a barrier before the air is conditioned and circulated throughout the building. HVAC filters vary in material, efficiency, and design—ranging from fibreglass mesh filters and pleated paper filters to HEPA (High Efficiency Particulate Air) filters and electrostatic filters. Each type offers different levels of filtration based on its MERV rating (Minimum Efficiency Reporting Value), which indicates how effectively it captures particles of various sizes.

In commercial and residential settings, HVAC filters help maintain a cleaner and healthier indoor environment, reduce wear and tear on system components, and enhance overall system performance. Regular maintenance and timely replacement of these filters are crucial to ensure optimal airflow, energy efficiency, and consistent air quality.

The construction of HVAC filters is engineered to effectively capture airborne particles while allowing sufficient airflow through heating, ventilation, and air conditioning systems. These filters are built with a combination of filter media, frame, and support structure, designed for durability, filtration efficiency, and compatibility with various system types.

At the core of every HVAC filter is the filter media, which is the material responsible for trapping particles. Common media types include fibreglass, synthetic fibres, pleated paper, polyester, or cotton blends. Higher-grade filters, such as HEPA or ULPA filters, use tightly woven microfibres capable of capturing extremely fine particles. The media is often arranged in a pleated configuration to increase surface area, which enhances dust-holding capacity and prolongs filter life without significantly restricting airflow.

The filter media is enclosed in a rigid or semi-rigid frame, typically made of cardboard, plastic, galvanised steel, or aluminium, depending on the application. This frame maintains the shape of the filter and provides structural support during airflow pressure. In pleated filters, a wire mesh backing or expanded metal grid is usually attached behind the media to prevent it from collapsing or deforming under high air pressure.

Some advanced HVAC filters include electrostatic charges embedded within the media to enhance particle attraction, or activated carbon layers to adsorb odours and volatile organic compounds (VOCs).

Overall, the construction of HVAC filters balances efficiency, airflow resistance, and durability, ensuring that they effectively protect both the HVAC system and indoor air quality across a wide range of commercial, industrial, and residential applications.

An Industrial Process Chiller is made up of several essential components that work together to regulate temperature and ensure smooth operation. Each part plays a crucial role in the refrigeration cycle:

Pre Filters are the first line of defence in air and water filtration systems, designed to capture larger particles such as dust, dirt, rust, and debris before they reach the main filter. By removing these impurities early, pre filters help extend the life of primary filters, enhance overall system performance, and reduce maintenance frequency. They are widely used in HVAC systems, air purifiers, RO water filtration units, and industrial processing systems.

Available in various materials such as synthetic fibres, stainless steel mesh, and pleated paper, pre filters can be tailored to suit different environments and filtration needs. Whether used in residential homes, commercial buildings, or industrial plants, pre filters play a crucial role in improving air and water quality, ensuring equipment longevity, and maintaining consistent operational efficiency.

Aluminum Filters are durable and reusable filtration solutions commonly used in HVAC systems, kitchen exhausts, air handling units, and industrial ventilation. Designed to capture grease, dust, and airborne particles, these filters are made from layers of expanded aluminium mesh that provide high dust-holding capacity while allowing maximum airflow. Their rigid construction and corrosion resistance make them ideal for long-term use in demanding environments.

These filters are lightweight, washable, and easy to maintain, offering a cost-effective alternative to disposable filters. Available in various thicknesses and sizes, aluminum filters can be customised to fit different system requirements. Whether for residential range hoods, commercial kitchens, or industrial air systems, aluminum filters help maintain cleaner air, reduce energy consumption, and improve the overall efficiency of your equipment.

Nylon Filters are versatile and highly durable filtration solutions used across a wide range of applications, from HVAC systems and industrial air filtration to water treatment and laboratory use. Made from woven or mesh nylon material, these filters are known for their excellent chemical resistance, high tensile strength, and ability to capture fine particles without restricting airflow or fluid movement.

Available in different micron ratings and mesh sizes, nylon filters are ideal for pre-filtration in air systems, dust collection, and liquid filtration where reusability and easy cleaning are essential. Their lightweight, washable nature makes them a cost-effective choice for long-term performance. Whether used in commercial ventilation units, aquariums, or industrial machinery, nylon filters deliver reliable protection against contaminants while maintaining optimal system efficiency.

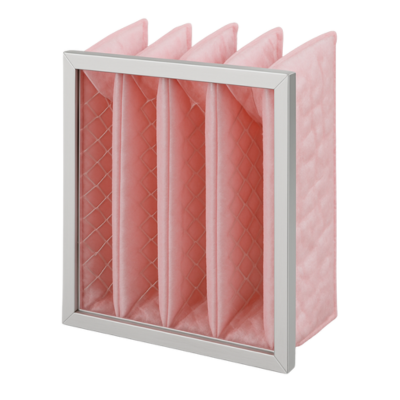

Bag Filters are efficient and economical filtration devices used to remove dust, debris, and fine particles from air and liquid systems. Commonly found in industrial ventilation, HVAC systems, dust collectors, and liquid processing units, bag filters offer high dirt-holding capacity and extended service life. Their deep-pocket design allows for maximum surface area exposure, ensuring effective filtration with minimal pressure drop.

Constructed from durable materials like synthetic fibres, polyester, or polypropylene, bag filters are available in various sizes, micron ratings, and configurations to meet diverse application needs. They are easy to install, replace, and maintain, making them an ideal choice for factories, cleanrooms, pharmaceutical units, and food processing facilities. Whether for air or liquid filtration, bag filters provide a reliable solution for maintaining clean environments and protecting downstream equipment.

HEPA Filters (High-Efficiency Particulate Air filters) are advanced air purification components designed to capture 99.97% of airborne particles as small as 0.3 microns. Commonly used in hospitals, laboratories, cleanrooms, and HVAC systems, HEPA filters are essential for maintaining sterile and contaminant-free environments. They effectively trap allergens, dust, bacteria, pollen, and even some viruses—making them ideal for both residential and commercial air filtration needs.

Built with densely packed fibres, HEPA filters offer high filtration efficiency while maintaining adequate airflow. They are available in various sizes and grades (such as H13, H14) to meet specific air quality standards. Whether used in air purifiers, HVAC units, or industrial clean air systems, HEPA filters ensure maximum indoor air quality and are a critical part of health and safety compliance in sensitive environments.

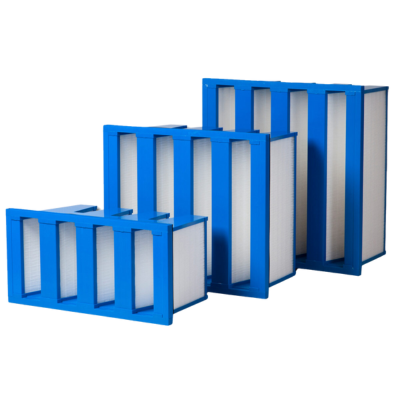

V Bank Filters are high-efficiency air filters designed with a unique “V-shaped” pleat configuration that maximises filtration surface area while maintaining compact dimensions. This design allows for higher dust-holding capacity, lower pressure drop, and extended service life—making them ideal for demanding air handling applications in commercial buildings, hospitals, cleanrooms, and industrial facilities.

These filters are typically made with synthetic or glass fibre media and housed in robust plastic or metal frames. V Bank Filters are suitable for use as final filters in HVAC systems or as pre-filters in ultra-clean environments where HEPA or ULPA filters are used downstream. Their energy-efficient performance and long replacement cycles help reduce operational costs while ensuring superior indoor air quality and consistent airflow.

Pleated Filters are high-performance air filters designed to provide enhanced surface area and improved dust-holding capacity compared to flat panel filters. By folding the filter media into pleats, these filters capture a greater volume of airborne particles such as dust, pollen, mould spores, and pet dander while maintaining a low pressure drop. Ideal for residential, commercial, and industrial HVAC systems, pleated filters offer a balanced solution for airflow efficiency and air quality.

Available in a range of MERV ratings, sizes, and media types, pleated filters are suitable for both standard and custom applications. They are easy to install and replace, offering consistent performance and extended service life. Whether you’re upgrading your building’s air filtration or maintaining a clean indoor environment, pleated filters deliver reliable protection for your HVAC equipment and the people who rely on it.