At Inventure, we offer a wide range of Pipe and Duct Flexible Connectors and Expansion Joints from Easyflex – India, providing durable and reliable solutions for controlling vibration, thermal expansion, noise, and movement in piping and ducting systems. These products are engineered to enhance system safety, efficiency, and longevity across diverse industrial and commercial applications.

Easyflex designs and manufactures expansion joints to offer a broader range of flexible piping solutions to customers across industries. Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Expansion joints are available in many different shapes and materials. At Easyflex, we design manufacture a wide range of metallic bellows and rubber expansion joints for a broad range of flexible piping solutions for various industries. Our design process allows us to customize expansion joints to the exact requirements and demands of our customers. We do offer stocked pre-engineered expansion joints for standard applications. Any pipe connecting two points is subjected to numerous types of action which result in stresses on the pipe.

Some of the causes of these stresses are…

Product Range

Metallic Expansion Joints

Rubber Expansion Joints

Hose Assemblies

Duct Flexible Connectors

Applications Across Industries

Our expansion joints and flexible connectors are widely used in:

The Inventure Advantage

An Industrial Process Chiller is made up of several essential components that work together to regulate temperature and ensure smooth operation. Each part plays a crucial role in the refrigeration cycle:

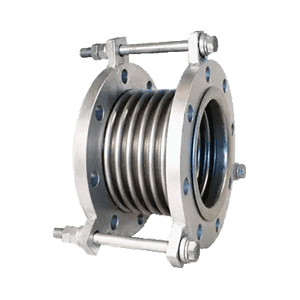

Metallic Expansion Joints are installed in pipe work and duct systems to prevent damage Metallic Expansion Joints are critical components in piping and duct systems, designed to absorb and compensate for thermal expansion, vibration, pressure thrust, and other mechanical stresses that can otherwise damage pipelines or connected equipment. By accommodating these movements, metallic expansion joints help maintain system integrity, reduce maintenance costs, and enhance operational reliability.

Design and Construction:

Applications:

Metallic expansion joints are widely used in industries that demand high reliability and performance, such as:

Benefits of Metallic Expansion Joints:

Bellows are a flexible piping element. The corrugation of the expansion joint is designed to be flexible in order to absorb pipe expansion and contraction due to changes in temperature. The number of corrugation of bellows is decided according to the displacement amount and the expansionary and contracting force that the bellows have to absorb. Bellows have to be strong to the design pressure and operating pressure of piping and installation and they also have to be flexible to absorb thermal movement. The thrust force of the flow in the piping has to be buttressed by things other than bellows.

The value of the thrust force of bellows is usually calculated by multiplying the value of the effective cross section area by the value of the flow pressure of pipe.

Easyflex Bellows are fabricated from cylindrical tubes made of high ductility material. The cylindrical body is formed onto parallel corrugations which accommodates all basic movements without encountering wear and tear as associated with conventional mechanical devices. Bellows are designed and manufactures as per the latest additions of EJMA, ASME, GIS, S, DIN, IS standards under the supervision of highly qualified team of engineers and technocrats.

To attain high flexibility and above average life expectancy, our Bellows are made from tested S. S. 316/321/304 stainless steel material. These bellows retain the flexibility when subject to internal pressure. Easyflex Bellows have proven their outstanding performance in a wide variety of applications.

Metal hoses are useful in a variety of different industrial applications including the transfer of air, gas and fluids. It is also used to balance thermal pressure and help with misalignment issues. Easyflex designs and manufactures high-performing metal hose assemblies that provide longevity, flexibility and strength to any application. We offer a broad range of corrugated inner core diameters and designs, multi braiding capabilities, and engineered assembly expertise to meet to most challenging applications.

Proper hose and fitting selection are critical to the safety of both your people and your profits, thus why the S.T.A.M.P.E.D acronym was created. The STAMPED acronym is an industry-wide standard that should begin every conversation when selecting a hose for a new application. STAMPED stands for: Size, Temperature, Application, Material, Pressure, Ends and Delivery.

Easyflex offers a wide variety of custom-built hose assemblies that are assembled in-house and have equipment experts that are trained to assess the needs of any application. Our hose assemblies are engineered to provide reliable presentation while integrating with the other equipment in the processing line to deliver maximum production output.

Flexible Metallic Hose Connections

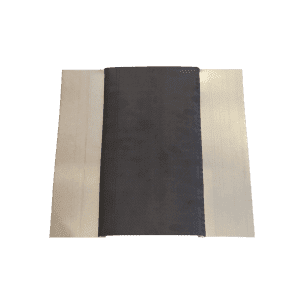

At Inventure, we offer high-quality Duct Flexible Connectors designed to isolate vibrations caused by air handling units (AHUs) and fans connected to air ducts. Installing a flexible duct connector joint between the outlet of these devices and the ductwork helps reduce noise, absorb vibration, and prevent mechanical stress, enhancing the longevity and performance of HVAC systems.

Design Features:

Benefits: