A heat exchanger is a mechanical device used to transfer heat between two or more fluids (liquid or gas) without allowing them to mix. It is commonly used in heating, cooling, and energy recovery applications across various industries such as HVAC, power generation, refrigeration, chemical processing, automotive, and food processing.

The core function of a heat exchanger is to efficiently move heat from one fluid to another—either to cool down a hot fluid, heat up a cold one, or recover waste heat from industrial processes. This is achieved through thermal conduction across a solid barrier, typically metal, that separates the two fluids. For example, in an HVAC system, a heat exchanger allows warm air to heat incoming cold air without mixing the two airstreams.

There are various types of heat exchangers, including shell and tube, plate, fin-tube, and coil-type designs, each suited to specific applications and performance requirements. They are designed to maximise surface area for heat transfer while minimising resistance to fluid flow.

By enabling efficient energy exchange, heat exchangers help reduce energy consumption, lower operational costs, and improve system performance, making them vital in both industrial and residential settings.

The construction of a heat exchanger is designed to facilitate efficient heat transfer between two fluids while keeping them physically separated. The materials, structure, and design vary depending on the type of heat exchanger and its intended application, but all are built to maximise thermal conductivity, durability, and flow efficiency.

The most common types—shell and tube, plate, and fin-tube heat exchangers—each have distinct construction features.

In a shell and tube heat exchanger, the construction includes a cylindrical shell (usually made of carbon steel, stainless steel, or copper alloys) that houses a bundle of metal tubes. One fluid flows through the tubes, while the other flows around them within the shell. The ends of the tubes are secured in tube sheets, and baffles are often added inside the shell to direct the flow and enhance turbulence, which improves heat transfer.

Plate heat exchangers are constructed from a series of thin, corrugated metal plates (commonly stainless steel or titanium) that are clamped together in a frame. Each alternate plate carries a different fluid, and the corrugation creates turbulence, increasing surface area and heat transfer efficiency. Gaskets or brazed joints seal the plates to prevent mixing of the fluids.

Fin-tube heat exchangers are made using metal tubes with extended surface fins attached to the outside. The fluid flows inside the tubes, while air or another fluid passes over the fins. The fins, typically made of aluminium or copper, increase the surface area and enhance heat exchange.

In all types, headers, nozzles, and mounting brackets are included for fluid entry and exit, support, and integration into the system. The entire assembly is pressure-tested and often includes corrosion-resistant coatings or insulation, depending on the environment. This robust construction ensures that heat exchangers perform efficiently, safely, and reliably in both industrial and commercial applications.

An Industrial Process Chiller is made up of several essential components that work together to regulate temperature and ensure smooth operation. Each part plays a crucial role in the refrigeration cycle:

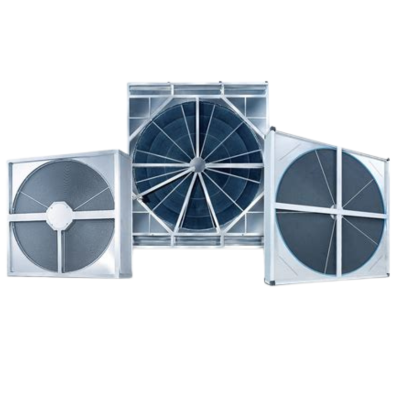

Rotary Heat Exchangers, also known as rotary wheels or thermal wheels, are advanced energy recovery devices used in HVAC systems to transfer heat and moisture between incoming and outgoing air streams. By rotating continuously between the supply and exhaust airflow, the exchanger captures sensible and latent heat from the outgoing air and transfers it to the fresh incoming air—significantly reducing energy consumption and improving indoor climate control.

These exchangers are commonly used in commercial buildings, data centres, hospitals, and industrial facilities where high ventilation rates are required without compromising energy efficiency. Rotary Heat Exchangers are available in various configurations, including hygroscopic (for moisture transfer) and non-hygroscopic (for sensible heat only) models. With high recovery efficiency, compact design, and low operational costs, they offer a sustainable solution for energy savings and improved indoor air quality.

Cross Flow Heat Exchangers are compact and efficient devices used to transfer heat between two perpendicular air streams without mixing them. Commonly used in ventilation and air handling units, this type of heat exchanger allows for effective recovery of sensible heat, helping to reduce the energy demand of HVAC systems while maintaining indoor air quality. The design ensures that incoming fresh air is pre-conditioned by outgoing exhaust air, improving overall system efficiency.

Made from materials like aluminium or plastic, cross flow heat exchangers are corrosion-resistant, lightweight, and suitable for a wide range of applications—from commercial buildings and hospitals to industrial facilities and cleanrooms. With their simple structure and reliable performance, they are an ideal solution for energy recovery in environments where maintaining separate airflow paths is critical. Their low maintenance requirements and high energy-saving potential make them a popular choice for modern ventilation systems.

Counter Flow Heat Exchangers are highly efficient thermal transfer devices designed to maximise heat recovery by allowing the hot and cold fluids to flow in opposite directions. This configuration ensures a greater temperature difference across the heat exchanger surface, leading to superior heat transfer performance compared to other flow designs. Counter flow heat exchangers are ideal for applications that demand high thermal efficiency, such as industrial processes, HVAC systems, and renewable energy systems.

These units are commonly constructed from stainless steel, copper, or aluminium, offering excellent corrosion resistance and durability under varying pressure and temperature conditions. Counter flow designs are particularly effective in liquid-to-liquid or gas-to-liquid systems where energy conservation and temperature control are critical. Their compact design, high performance, and minimal thermal losses make them a preferred solution for modern, energy-efficient operations.