Inventure offers wide range of heaters from DIRAC Industries – Chez Republic.

DIRAC excel in providing advanced electrical heating solutions and control

systems for industrial thermal processes. With over six decades of industry

experience, DIRAC Industries stands as a leading manufacturer of high-quality

heating elements and control boxes, designed to optimize efficiency and

reliability in diverse thermal applications.

heating elements and control boxes, designed to optimize efficiency and

reliability in diverse thermal applications.

Unwavering Commitment to Quality

Our unwavering commitment to quality is reflected in every product we offer. By leveraging advanced technologies and adhering to rigorous standards, we ensure that our heating solutions deliver exceptional performance and safety. Whether you require custom-designed heating elements or sophisticated control systems, DIRAC Industries possesses the expertise to meet your specific requirements.

Wide Range of Solutions

Explore our extensive range of heating solutions tailored for various industries, including offshore, utility construction, industry, and shipbuilding. From design to installation, we provide turnkey solutions with comprehensive support throughout the project lifecycle.

Enhance Your Thermal Processes

Discover how DIRAC Industries can elevate your thermal processes and enhance operational efficiency. Contact us today to discuss your heating

needs and leverage our expertise to achieve precise and reliable thermal control. Partner with us to influence the future of industrial heating technology.

Our Product Range

We specialize in a broad array of products designed for heating or maintaining temperatures of gases, liquids, or solids with precise regulation. Our product range includes:

Each product is meticulously engineered to ensure precise temperature control and safety across diverse thermal applications, providing comprehensive solutions for your heating requirements.

Specialized Products

In addition to our standard offerings, which are often customized to meet specific needs, DIRAC Industries specializes in crankcase heaters and heating mats for the heat pump industry, as well as custom-made heating mats and plates for the food transport industry. These specialized products are individually tailored to each customer’s requirements and are manufactured on a mass scale to ensure consistent quality and performance. Contact us to explore how our tailored heating solutions can optimize your operations.

An Industrial Process Chiller is made up of several essential components that work together to regulate temperature and ensure smooth operation. Each part plays a crucial role in the refrigeration cycle:

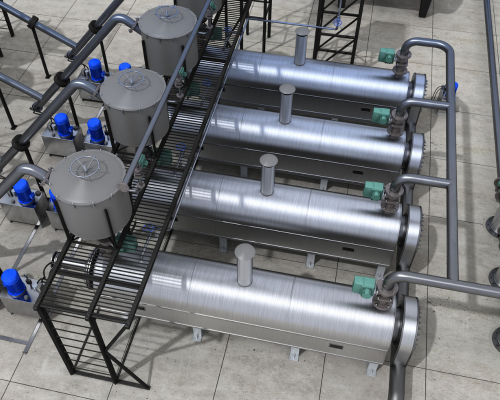

At Invneture, we provide specialized services for a wide range of Steam Equipment used across various industrial and commercial applications. Steam equipment, including boilers, steam traps, valves, and piping systems, plays a crucial role in processes requiring heat and moisture control. Our expertise ensures that your steam systems operate safely, efficiently, and reliably, supporting smooth production and operational continuity.

Our team offers comprehensive solutions including installation, routine maintenance, troubleshooting, and repairs for all types of steam equipment. We understand the critical importance of steam system efficiency in energy conservation and cost reduction, and therefore, focus on optimizing equipment performance while minimizing downtime. Whether you require preventive maintenance or emergency support, Invneture delivers prompt and professional service tailored to your specific steam equipment needs.

Choosing Invneture means entrusting your steam systems to skilled technicians dedicated to maintaining safety standards and operational excellence. We work closely with you to ensure compliance with industry regulations while extending the lifespan of your steam equipment. Contact Invneture today for reliable, cost-effective steam equipment services that keep your operations running at peak efficiency.

At Invneture, we specialize in expert services for Steam Traps, essential components in steam systems that efficiently discharge condensate and non-condensable gases while preventing steam loss. Proper functioning of steam traps is vital to maintaining system efficiency, reducing energy waste, and ensuring the safety and reliability of industrial and commercial steam applications. Our team understands the critical role steam traps play in optimizing heat transfer and maintaining smooth process operations.

We provide comprehensive steam trap solutions including inspection, testing, repair, and replacement services. Using advanced diagnostic tools, our technicians identify malfunctioning traps and recommend timely interventions to prevent costly downtime and energy losses. Whether your facility uses mechanical, thermostatic, or thermodynamic steam traps, Invneture offers tailored maintenance programs to maximize their performance and longevity.

Partnering with Invneture guarantees expert care and proactive management of your steam trap systems. We prioritize efficiency, safety, and compliance, helping you reduce operational costs while improving system reliability. Contact Invneture today to ensure your steam traps operate at peak efficiency and support your business’s sustainable steam management goals.

At Invneture, we provide specialized services for Steam Water Separators, critical devices used to remove water droplets from steam to ensure dry and efficient steam flow in industrial systems. By separating condensate and moisture from steam, these units protect equipment, improve heat transfer efficiency, and prevent damage caused by water hammer and corrosion. Proper operation of steam water separators is essential for maintaining system reliability and energy efficiency.

Our expert team offers installation, inspection, maintenance, and repair services tailored to a variety of steam water separator models and applications. We use advanced techniques to assess separator performance, diagnose issues, and provide effective solutions to optimize steam quality and system safety. Whether you require routine servicing or urgent repairs, Invneture ensures minimal downtime and maximized operational efficiency.

Choosing Invneture for your steam water separator needs means partnering with professionals committed to delivering reliable, energy-saving steam system solutions. We work closely with clients to enhance system longevity and comply with industry safety standards. Contact Invneture today to keep your steam systems running smoothly with expertly maintained steam water separators.